Cable DMX512. Standard cables for the DMX 512 signal.

A robust DMX512 system starts with high quality cables of a certain type. If the reliability of the system is very important, then first of all you should pay attention to the cables and connectors, and also to their correct installation. You can build a DMX system and use second-rate cables (and even ordinary electrical wires like those that go to your electric bell), however on one nightmarish day such a system can suddenly fail without any visible Reasons in the midst of an important show.

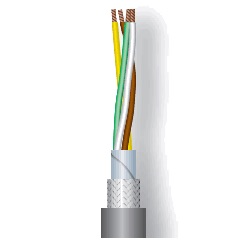

The cable must comply with the EIA485 standard (RS485) and consist of one or two low-capacitance twisted pairs, braided and screened with foil. In order for the wires to have sufficient mechanical strength and minimum voltage drop on long lines, they must correspond to the American wire gauge of 24 AWG (7 / 0.2) or higher.

The second pair of wires can be present in the cable as a spare, or can be used to transmit other signals. Some dimmers use this pair to report faults and the status of the dimmer. Check if your DMX uses the second pair (currently, in most cases, this pair is not used).

When you are wiring for permanent use, it is recommended that you use cables with at least two twisted pairs in order to be able to use these lines with future versions of the DMX512 protocol. Currently, some manufacturers are already releasing systems using a second twisted pair to transfer information from dimmers to the console. In addition, the additional twisted pair will not interfere if there is an open or short on the main pair.

The cable shield is connected to the pins of connector 1. The first (main) twisted pair is connected to pins 2 and 3. The second twisted pair (if any) is connected to pins 4 and 5. The screen MUST be connected at both ends of the cable even if the receiver is not grounded. Otherwise, the cable will not be shielded.

Cable types.

The «Cable Type Table» in the appendix at the end of this manual is not a complete list of all cables that may be suitable for use with the DMX512. For this purpose, any twisted-pair cable with a wave impedance of 120 Ohms, shielded and conforming to the EIA485 standard, is suitable. The cable assortment required will depend on the length of the line, but it is recommended to use cables with ordinal numbers of at least 22 AWG, 24 AWG.

AWG stands for American Wire Gauge. H E

Cable Table

Cable Type Table

| Type: | Pairs: | ZW: | Jacket: | AWG | Use: | Temp: |

|---|---|---|---|---|---|---|

| Belden cables: | ||||||

| 1162A | 1 | 100 | PVC | 20 | UL2498 | 80 |

| 1215A | 2 | 150 | PVC | 26 | IBM type 6 office cable | 75 |

| 1269A | 2 | 100 | PTFE | 22 (solid) | High temp, Plenum cable | 200 |

| 8102 | 2 | 100 | PVC | 24 | UL2919 | 80 |

| 8132 | 2 | 120 | PVC | 28 | UL2919 | 80 |

| 8162 | 2 | 100 | PVC | 24 | UL2493 | 60 |

| 8227 | 1 | 100 | PVC | 20 | UL2498 | 80 |

| 82729 | 2 | 100 | PTFE | 24 | High temp, Plenum cable | 200 |

| 88102 | 2 | 100 | PTFE | 24 | High temp, Plenum cable | 200 |

| 89182 | 1 | 150 | PTFE | 22 | High temp, Plenum cable | 200 |

| 89207 | 1 | 100 | PTFE | 20 | High temp, Plenum cable | 200 |

| 89696 | 2 | 100 | PTFE | 22 | High temp, Plenum cable | 200 |

| 89729 | 2 | 100 | PTFE | 24 | High temp, Plenum cable | 200 |

| 89855 | 2 | 100 | PTFE | 22 | High temp, Plenum cable | 200 |

| 9182 | 1 | 150 | PVC | 22 | UL2668 | 60 |

| 9207 | 1 | 100 | PVC | 20 | Flame-proof | 75 |

| 9271 | 1 | 124 | PVC | 25 | UL2092 | 60 |

| 9729 | 2 | 100 | PVC | 24 | UL2493 | 60 |

| 9804 | 2 | 100 | PVC | 28 | UL2960 | 60 |

| 9829 | 2 | 100 | PVC | 24 | UL2919 | 80 |

| 9841 | 1 | 120 | PVC | 24 | UL2919 | 80 |

| 9842 | 2 | 120 | PVC | 24 | UL2919 | 80 |

| Proplex cables: | ||||||

| PC222P | 1 | 110 | Polyurethane | 22 | Heavy duty and portable | 105 |

| PC222T | 1 | 110 | PVC | 22 | UL2464 | 105 |

| PC224P | 2 | 110 | Polyurethane | |||

| PC224T | 2 | 110 | PVC | 22 | UL2464 | 105 |

| PC226T | 3 | 110 | PVC | 22 | UL2464 | |

| Alpha cables: | ||||||

| 9109 | 1 | 100 | FEP | 20 | High temp | 150 |

| 9816 | 1 | 95 | PVC | 18 | Large diameter | 80 |

| 9817 | 1 | 100 | PVC | 20 | UL2498 | 80 |

| 9818 | 1 | 100 | PVC | 20 | ||

| 9818D | 1 | 100 | Polyurethane | 20 | Direct burial | 80 |

| 9821 | 1 | 124 | PVC | 25 | UL2092 | 80 |

| 9823 | 1 | 150 | PVC | 22 | UL2772 | 80 |